Stair Design

To determine the details to best fit the space and have the correct flow of travel. Engineered size and shape beams treads. To match the style of the home.

1. Typical stairs ascend 9′ to 12′ in elevation.

2. Spiral/Curved stairs are typically 90 to 180 degrees in travel.

*Over 180 degrees must become a tighter radius. This adds to the cost. Stairs may also change shape such as flare bottom with wide and curved nose steps, projecting starting step. These also will add costs. The treads must be 6″ at the narrow and 9″ to 10″ at the travel line. Open riser treads are 3″ or more thick. This keeps the horizontal gap between treads under 4″. Spiral beams are standard 3″ to 4″ thick and 11″ to 16″ wide to carry spans.

*Stairs with long unsupported spans and more radius will have some movement. Design includes a plan view drawing and 3D view. CADD design will be an hourly rate.

Price

These are the PRIMARY factors that determine the price of the spiral stair by design;

1.HEIGHT

2.TREAD COUNT

3.WIDTH

4.DEGREE OF SPIRAL

5.TIGHT SPIRAL

6.WOOD SPECIES

Style

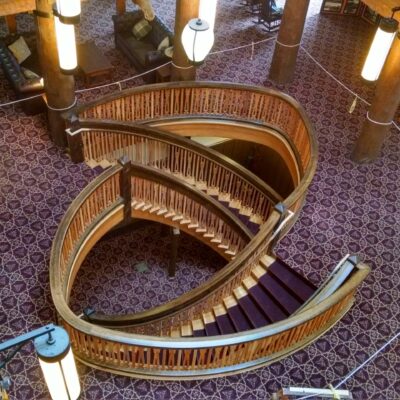

My Flagship Stairs are Free Span with helical beams open riser treads.

Also availible are Enclosed Stairs with risers and open tread ends.

Both free span and wall under are availible. Wall supported stairs offer a savings.

General Rule for stairs is, the more wood finishes the more it will cost.

Species

All stairs are a solid wood engineered core. Base price species include Red Alder and Western Fir. Next level would be Oak and Coastal Maple. Ascending in value Cherry, Walnut and Exotic woods.

*Some exotic wood species do not bend well and glue poorly. Hardwood veneers are 3/16″ to 1/4″ thick adding stability

Stair Structure

Spiral Stair is priced only for the beams and treads without rails. This allows for the selection of posts, balusters, loft rails and other factors. These parts vary in price and method of install.

Rails

Rails are cut from a single piece usually 8′ to 10′ and joined for long rail sections. Standard rail profile is 2-3/8″ wide X 2-5/8″ tall, rounded top with finger grove. Rails are made continuous to meet code.

Loft Railings

All railings adjacent to stairs will be bid separately. This includes posts,

balusters, rails, floor cap or shoe rails. Installation of these rails may be more cost effective to contract local qualified carpenters.

Balusters

Wood or Iron, balusters provide the protection while adding to the look

and design. Iron gives an open feel allowing more view. Wood is warm and more traditional. Both can be color adjusted to match other elements from the home. The install varies with iron being less cost per baluster.Iron balusters come prefinish, wood do not. Spacing of balusters must not excede 4-1/4″ between. Iron balusters cost $7 to $20 each.Wood balusters cost $10 to $50.

Install

Arrangments must be made to have help to unload and move stair beams. These can weigh up to #400 and usually require 4 to 5 able body people to maneuver. No further assistance will be needed for the install. The stair structure usaully installs within 6 to 8 hours. The rails require more time.

*NOTE- The attachment of the top of beams require solid backing beam 3″ minimum. Also, steel plate attachment may require drywall repair

Newel Posts

Can be ordered from outside sources or custom made in shop. Typically the starting posts are larger than the loft or second level posts. Posts 5″ to 6″ starting posts with 4″ inch for the level or loft posts. Posts can vary $200 -$1000.

*Allowance budget provided for posts.

Delivery

All Stairs are prebuilt in shop disassembled and labeled. Treads are 3/8″mortised into beams and bolted with proprietary hidden system. Balusters are pre-mortised in beams and rails. Rails are joined and pre-cut. All stairs are carefully packaged and secured for delivery. Pricing for delivery is based on milage from Kalispell Montana Crating and shipping is available, price will vary due to size of stair beams and weight

Finishing

Stairs are typically delivered unfinished. Pre-finished spiral beams do not travel well. Spiral rails must be sanded in place. Exceptions to this could be posts and balusters Pre-finishing the treads with a floor finish upon request. A local painting contractor custom finishing your staircase is prefered.

Payment

To begin the process a 50% deposit is required. Payments at completion of the stairs can vary depending on the install timing. Most common is final payment at install. A delayed install may require 25% payment.